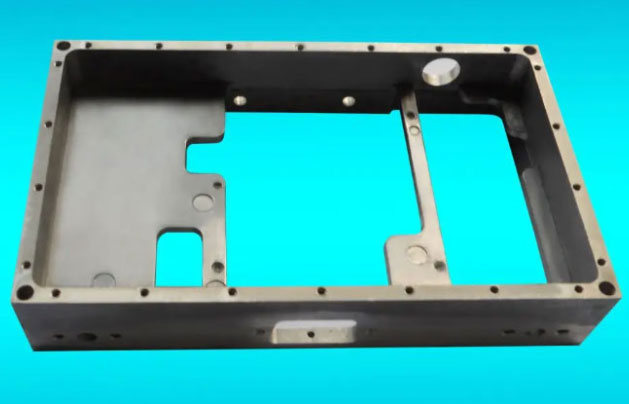

Many times, I will encounter some large aluminum alloys. If the aluminum alloy has a low hardness, it is easy to deform after processing. If you encounter some large aluminum alloy die castings, in order to prevent deformation, you must prevent deformation before drilling and roughing. The contour structure is roughly opened, the front and rear surfaces are flattened to be vertical, and then the front and back sides of the light knife are made by a machine. If the side wall of the workpiece is very thin, it must be heat hardened before placing the machine. It can also be left on the thickness according to the structure of the workpiece. Then straighten the perpendicularity of the parallelism of the workpiece, and draw the entire plane of the workpiece. It can also solve the problem of workpiece deformation.

If it is a relatively small workpiece, the product plane should be flush with the worktable, and there should be no gap when making the reverse side. Then the back can be used to solve the problem of deformation, or when the wool is first flattened, this surface can be used as the bottom surface. Then use the other side as the front side so that the workpiece can be vertical and the workpiece will not deform too much. For some thinner workpieces, it is reasonable to make side fashion clips. It is impossible to clamp the workpiece without strength and the bow clamp. It is best to flatten the workpiece with a right-angle iron, and then use a bow clamp to press the workpiece to a place where the right-angle iron is flat. In many cases, deformation is caused by unreasonable clamping, so reasonable clamping can prevent deformation.