CNC Machining Services

Mould-in-China is an international provider of high-quality CNC machining services. A large array of sophisticated CNC turning and milling machines and the latest supporting technology allows us to deliver customised parts with incredible precision.

Our collection of 3-, 4-, and 5-axis CNC machines grant us capabilities to approach widely-varying projects for a host of applications over a massive span of industries.

Precise cuts and a variety of allowable materials make CNC machining a preferred solution for prototyping, small-batch manufacturing, and low-volume manufacturing.

WHAT IS CNC MACHINING?

CNC is the acronym for Computer Numeric Control. In CNC Machining computers are used to input measurements and cutting data, guiding machines for extremely accurate operation. Talented engineers input layers of data into the machines to establish exact measurements, finishes, and production times.

The CNC process is reductive, beginning with a solid piece of material then steadily and accurately removing layers, revealing the design encased within. This is done using one of two processes: CNC milling and CNC turning.

CNC Milling

Mould-in-China is a professional provider of CNC machining services with advanced 3-, 4-, to 5- axis milling centers. We offer custom CNC milling for various industries worldwide. Our precision 3-, 4- and 5-axis CNC milling centers and experienced team guarantee our incredible CNC capacity, enabling us to handle the whole stage of the milling process easily from designing, prototyping, manufacturing, to final transportation.

With excellent capabilities and extensive expertise, we can provide top-grade but cost-effective custom CNC machining services from China, including 3-, 4-, and 5-axis milling for high-speed CNC manufacturing and rapid prototyping, and precision CNC turning. Our high-quality milled products are involved in the field of automation design, machine tool machining, medical equipment, lighting parts machining, etc.

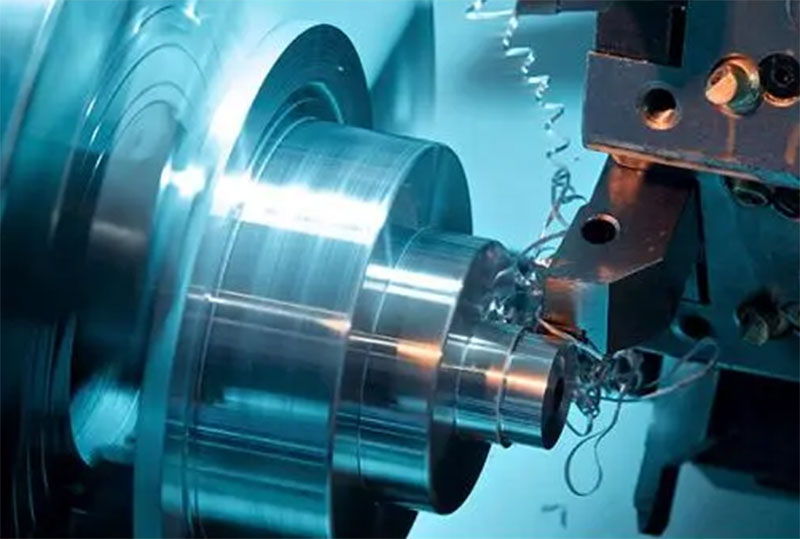

CNC Turning

CNC turning (also known as CNC lathes) is a subtractive manufacturing process in which a stationary cutting tool removes material by making contact with the spinning workpiece to create the desired shape.

During processing, a blank bar of stock material is held in the chuck of the spindle and rotated with the spindle. Extreme precision and repeatability can be achieved under the control of computer instructions for the movement of the machinery.

When CNC turning rotates the workpiece in a chuck, it’s generally to create round or tubular shapes and achieve far more accurate rounded surfaces than CNC milling or other machining processes.

SUPPORTED MATERIALS

CNC milling and turning can be performed on a huge variety of metals and different plastic materials, the more common being: Copper, Titanium, Aluminum, Stainless steel, Magnesium, Brass, Nylon, Polycarbonate

We can produce CNC milled and turned parts in dozens of additional materials. If you’re curious to know which material is right for you, send us a line. Our designers and engineers will put their experience to work for you, helping determine the best possible materials and manufacturing solution for your prototype or manufacturing run. Your design, required tolerances, and budget will all help determine which materials are necessary and appropriate for your project.