Sheet metal parts play a pivotal role in various industries, from construction and automotive to aerospace and electronics. Their versatility, durability, and cost-effectiveness make them an indispensable component in modern manufacturing processes. In this article, we will delve into the world of sheet metal parts, exploring their manufacturing techniques, applications, and the numerous benefits they offer.

Understanding Sheet Metal Parts

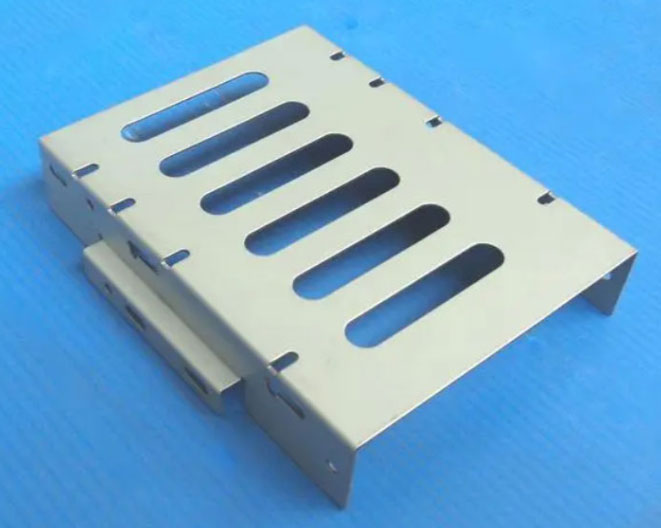

Sheet metal parts are thin, flat pieces of metal that undergo various fabrication processes to achieve specific shapes and sizes. These processes primarily involve cutting, bending, and assembling the metal sheets to form the desired component. The metals commonly used for sheet metal parts include steel, aluminum, copper, brass, and stainless steel, each chosen for its unique properties and suitability for particular applications.

Manufacturing Techniques

Cutting: The first step in manufacturing sheet metal parts is cutting the raw metal sheets to the required dimensions. Traditional methods include manual cutting with shears or saws, while modern techniques employ laser cutting, water jet cutting, and plasma cutting for higher precision and efficiency.

Bending: Once the metal sheets are cut, they are bent into the desired shape. This process is often performed using press brakes or roll-forming machines, where the metal is carefully shaped without losing its structural integrity.

Stamping: Stamping is a mass-production technique used to create multiple identical sheet metal parts. A die and a punch are used to cut the metal sheets into the desired shape quickly and consistently.

Welding and Joining: Sheet metal parts are often joined together using various welding techniques such as spot welding, TIG welding, or MIG welding. Additionally, fasteners like screws, nuts, and bolts are used for assembly.

Applications of Sheet Metal Parts

Sheet metal parts find application in a wide range of industries and products:

Automotive Industry: From car bodies to exhaust systems, sheet metal parts are extensively used in the automotive sector due to their strength and lightweight characteristics.

Construction Sector: Sheet metal parts are vital in the construction of buildings, bridges, and infrastructure due to their durability and ability to withstand harsh environmental conditions.

Electronics and Appliances: Devices like computers, refrigerators, and air conditioners rely on sheet metal parts for their outer casings and internal components.

Aerospace Industry: Sheet metal parts are crucial in aircraft manufacturing, providing aerodynamic and structural components.

Medical Equipment: Many medical devices and equipment are crafted from sheet metal due to its hygienic properties and ease of cleaning.

Consumer Goods: Various everyday items like metal furniture, kitchenware, and decorative pieces are made using sheet metal.

Benefits of Sheet Metal Parts

Strength and Durability: Sheet metal parts offer excellent strength and durability, ensuring long-lasting performance even under challenging conditions.

Cost-Effectiveness: Compared to other materials, sheet metal is relatively cost-effective, making it an economical choice for mass production.

Design Flexibility: Manufacturers can easily shape and mold sheet metal parts into complex designs, offering design flexibility and creative freedom.

Recyclability: Sheet metal is highly recyclable, contributing to sustainable and eco-friendly manufacturing practices.

Heat and Electricity Conductivity: Certain sheet metal alloys possess excellent heat and electricity conductivity, making them ideal for specific electronic applications.

Corrosion Resistance: Stainless steel and other corrosion-resistant sheet metals ensure longevity and reduced maintenance requirements.

Conclusion

Sheet metal parts are an integral part of modern manufacturing, catering to a diverse range of industries and applications. Their versatility, strength, and cost-effectiveness have solidified their position as one of the most sought-after materials for various products and structures. As technology advances, we can expect further improvements in sheet metal manufacturing techniques, expanding their utility and paving the way for more innovative designs and applications.