CNC machining is a manufacturing process that utilizes computer-controlled machines to produce precise and complex parts. It is a highly efficient and accurate method of producing parts that are used in a wide range of industries, including aerospace, automotive, medical, and electronics.

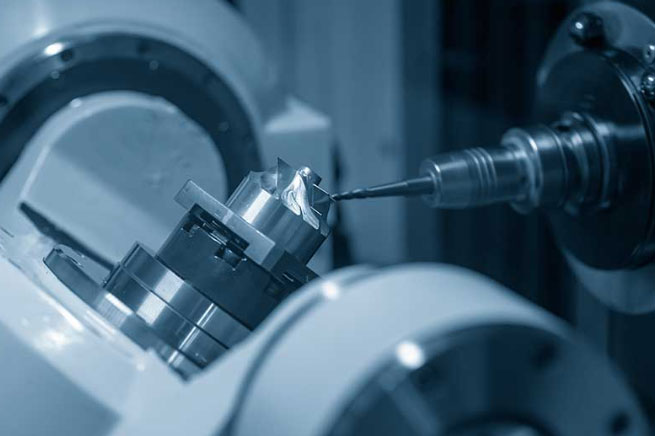

The CNC machining process involves several steps. First, a design is created using computer-aided design (CAD) software. The design is then converted into a set of instructions that the CNC machine can understand, known as G-code. The G-code is then loaded into the machine, and the machining process begins.

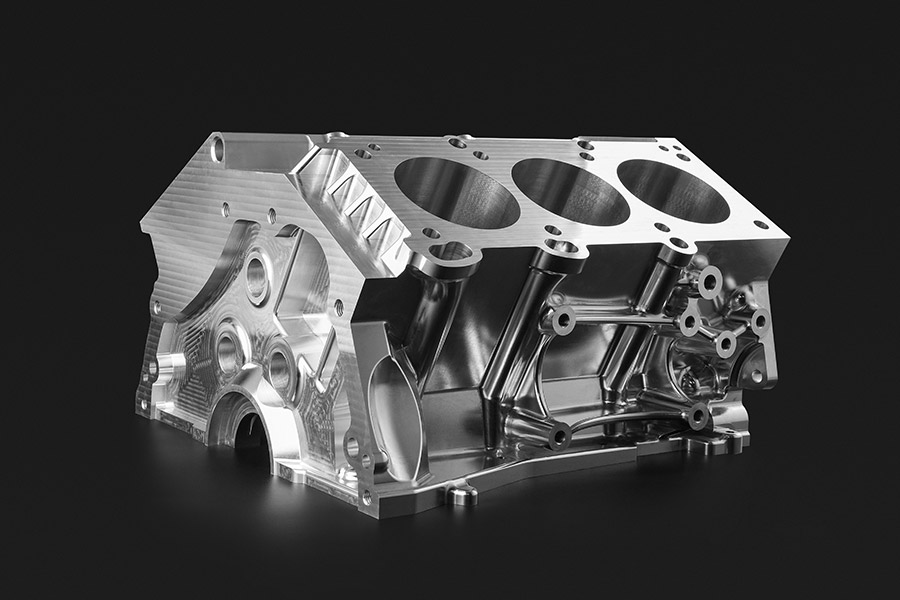

During the machining process, the machine removes material from a workpiece using various cutting tools. The cutting tools are controlled by the machine’s computer, which ensures that the cuts are made with extreme precision and accuracy.

One of the key advantages of CNC machining is its ability to produce parts with high levels of consistency and repeatability. This makes it an ideal process for producing large quantities of identical parts.

Overall, CNC machining process is a highly effective and efficient manufacturing process that has revolutionized the way parts are produced. Its ability to produce precise and complex parts with consistency and repeatability has made it an essential process in many industries.