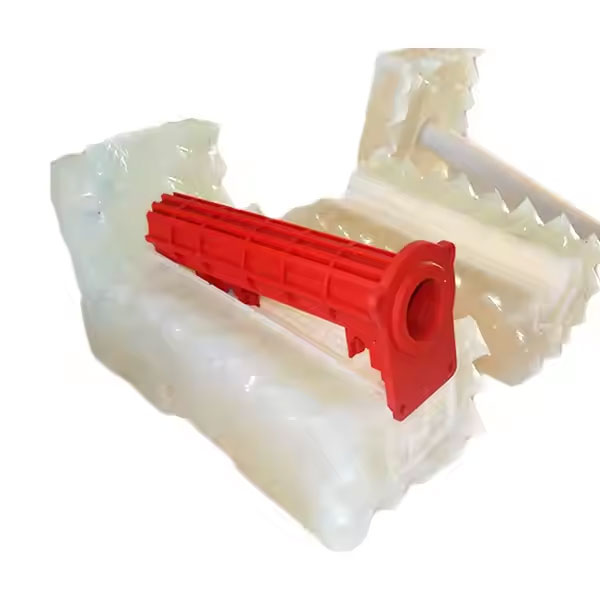

Vacuum casting is a manufacturing process used to produce small quantities of high-quality plastic parts. This process involves creating a silicone mold of the desired part and then injecting liquid plastic into the mold under vacuum pressure. The vacuum pressure ensures that the plastic fills the mold completely and evenly, resulting in parts that are highly accurate and detailed.

Vacuum casting is a popular choice for prototyping and low-volume production runs because it is relatively quick and cost-effective. It is also a good option for producing parts with complex geometries or fine details that cannot be achieved with other manufacturing processes.

One of the benefits of vacuum casting is that it allows for a wide range of materials to be used, including ABS, PC, PP, and more. This flexibility makes it possible to create parts that have specific properties such as flexibility or high-temperature resistance.

Overall, vacuum casting is a versatile and efficient manufacturing process that has many applications in industries such as automotive, aerospace, and medical devices.